<3%

bottom ash loss on ignition≥99.9%

burnout rate300 t/d (331 short tons/d)

treatment capacityGCCF

The GCCF, powered by the Gas-Char Complementary Combustion process and advanced small-scale reciprocating grate technology, enables efficient waste disposal with a smaller footprint, lower cost, and higher environmental standards. Its modular construction and intelligent operation provide a reliable, localized solution for sustainable waste management.

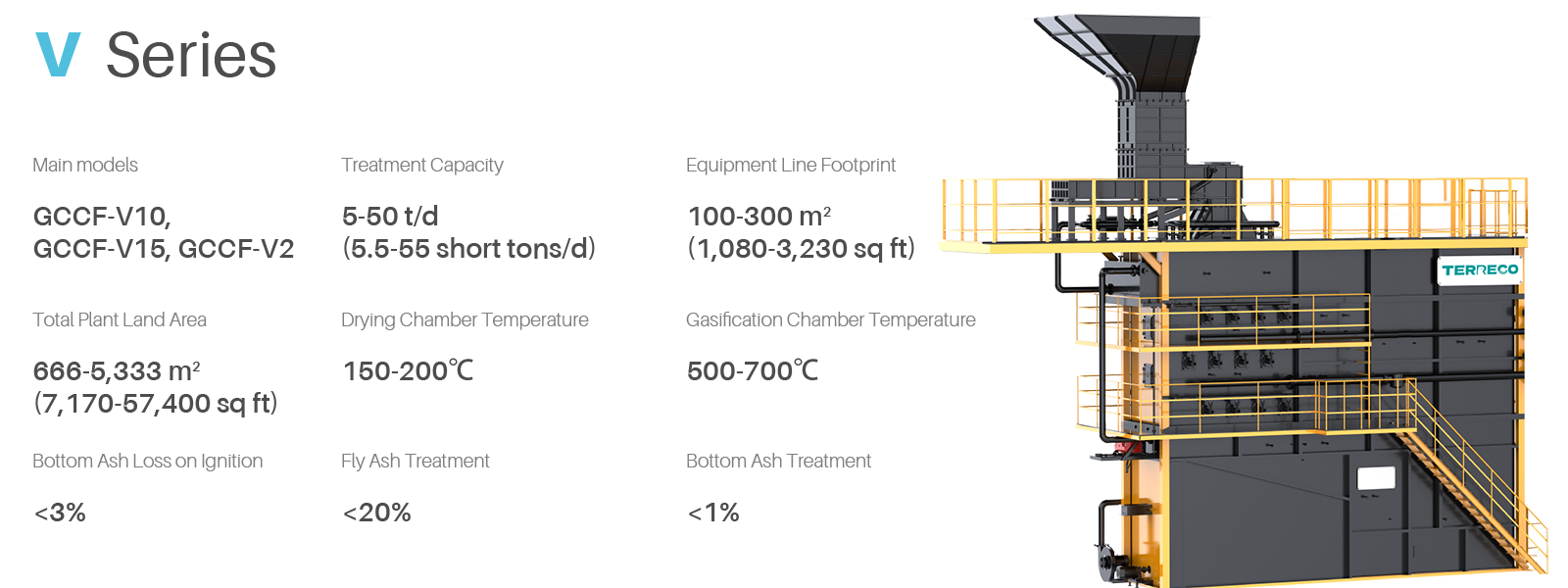

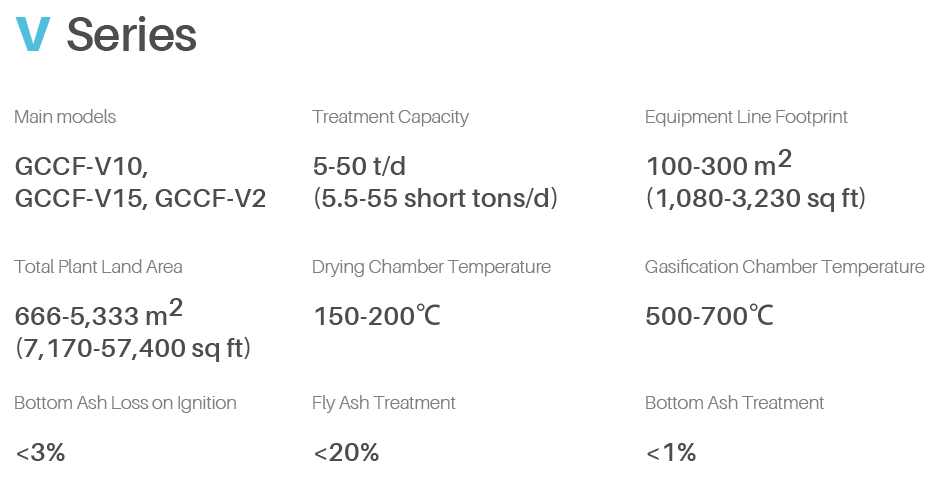

Detailed Specifications

Supporting Components

Product Highlights

<3% bottom ash loss on ignition | ≥99.9% burnout rate | Meeting combustion standards of > 850°C and > 2s flue gas retention time

Rapid Deployment

Modular furnace casting – Assembly time reduced by 50%, smaller footprint

Gas-Char Complementary Combustion

1. < 3% bottom ash loss on ignition

Smart Operation

Featuring AI-based combustion control, cross-regional remote centralized management, and real-time equipment visualization.

Near-Zero Emissions

1. Baghouse dust collector

Cost- and Energy-Efficient

1. No waste sorting requiredGas-Char Complementary Combustion Process

Inside the furnace, waste undergoes drying and pyrolytic gasification, producing gaseous combustibles and solid char. The gas and solid phases complement each other in the combustion zone, where intense burning creates a uniform temperature field, enabling stable and efficient treatment.

Grate System

The grate system consists mainly of a tilting grate and a reciprocating grate. Through precise mechanical motions, they enable orderly movement of materials within the furnace, ensuring complete combustion.Turning Waste Heat into Power

The GCCF captures thermal energy from high-temperature flue gas and repurposes it to generate steam, electricity, or cooling, maximizing energy reuse, reducing operating costs, and advancing carbon reduction goals.

Steam Supply

Provides on-site steam generation and mobile steam distribution for industrial and commercial applications.

Heating

Supports district heating in winter through efficient thermal energy recovery.

Power Generation

Enables distributed power generation and energy storage, grid-connected power sales, and EV charging applications.Smart Cloud Control Platform for GCCF

The GCCF is equipped with a cloud-based intelligent control platform powered by AI algorithms that optimize combustion parameters in real time, enabling adaptive operation and predictive alerts for truly unmanned operation. AI-Powered Combustion Optimization

AI-Powered Combustion Optimization

Automatically adjusts operating parameters through AI algorithms.

Visualized Central Control

Visualized Central Control

Provides end-to-end monitoring and cloud-based centralized management.

Unmanned Operation

Unmanned Operation

Ensures 24/7 operation with online CO monitoring.

AI-Powered Combustion Optimization

AI-Powered Combustion Optimization

Automatically adjusts operating parameters through AI algorithms.

Visualized Central Control

Visualized Central Control

Provides end-to-end monitoring and cloud-based centralized management.

Unmanned Operation

Unmanned Operation

Ensures 24/7 operation with online CO monitoring.

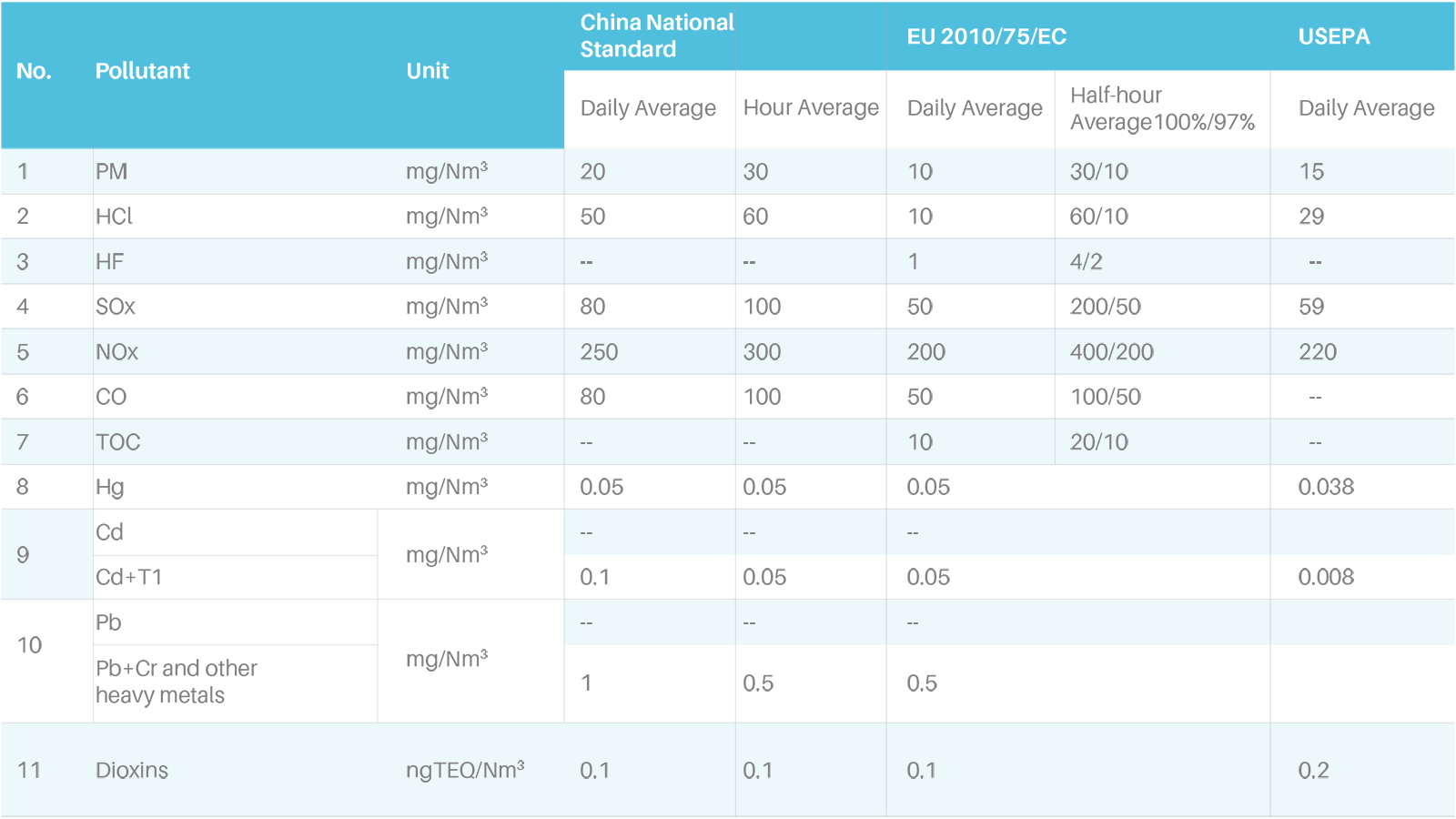

Global Standard Emission Performance

GCCF’s emission performance meets U.S., EU, and China standards, ensuring compliance with strict environmental regulations and achieving ultra-low emission levels.

Comparative Flue Gas Emission Standards: China vs EU vs US EPA(dioxin emissions far below EU limits)

GCCF Application Cases

Diverse Application Scenarios

Village & Township Waste Treatment

Providing nearby harmless disposal solutions to reduce operating costs.

Remote Area Waste Treatment

Ensuring reliable waste treatment for regions with limited grid coverage and poor transportation access.

Scenic Area Eco-Treatment

Providing waste disposal with minimal environmental impact while preserving natural ecosystems.

Island & Border Waste Treatment

Delivering reliable and independent waste treatment solutions for special environments.Get Your Tailored Technical Solution & Project Quote

customerservice@terreco.net